Picture this: you’ve just designed a sweet photo tee for Mom’s birthday, and you’re staring at two price quotes—one from a DTG shop, the other from a screen printer. You wonder, “Which will actually look as crisp as my vision?”

In our experience at heartful.gifts, that moment of doubt is super common. DTG (direct‑to‑garment) and screen printing each have their own strengths, but when it comes to quality, the differences can feel like night and day.

Think about the kind of artwork you’re putting on the shirt. If it’s a colorful family portrait with subtle gradients, DTG usually captures those details better because the printer sprays ink straight onto the fabric, pixel by pixel. It’s kind of like an inkjet printer for paper, only the paper is a soft cotton tee.

On the other hand, if you’re after bold, solid colors—say a simple “Best Dad Ever” slogan in bright red—screen printing often gives a richer, more vibrant finish. The ink sits on top of the fibers, creating a thick layer that doesn’t fade as quickly after repeated washes.

But here’s the kicker: the final quality isn’t just about the method, it’s also about the fabric, the ink, and the printer’s skill. A low‑grade cotton shirt can make a top‑notch DTG print look dull, while a premium screen‑printed job on cheap material can peel off after a few cycles.

So, what should you keep in mind when you compare “dtg vs screen printing quality”? First, look at the image complexity. Second, consider the number of colors and whether you need fine detail. Third, think about how often the item will be washed—gifts that get a lot of love need durability.

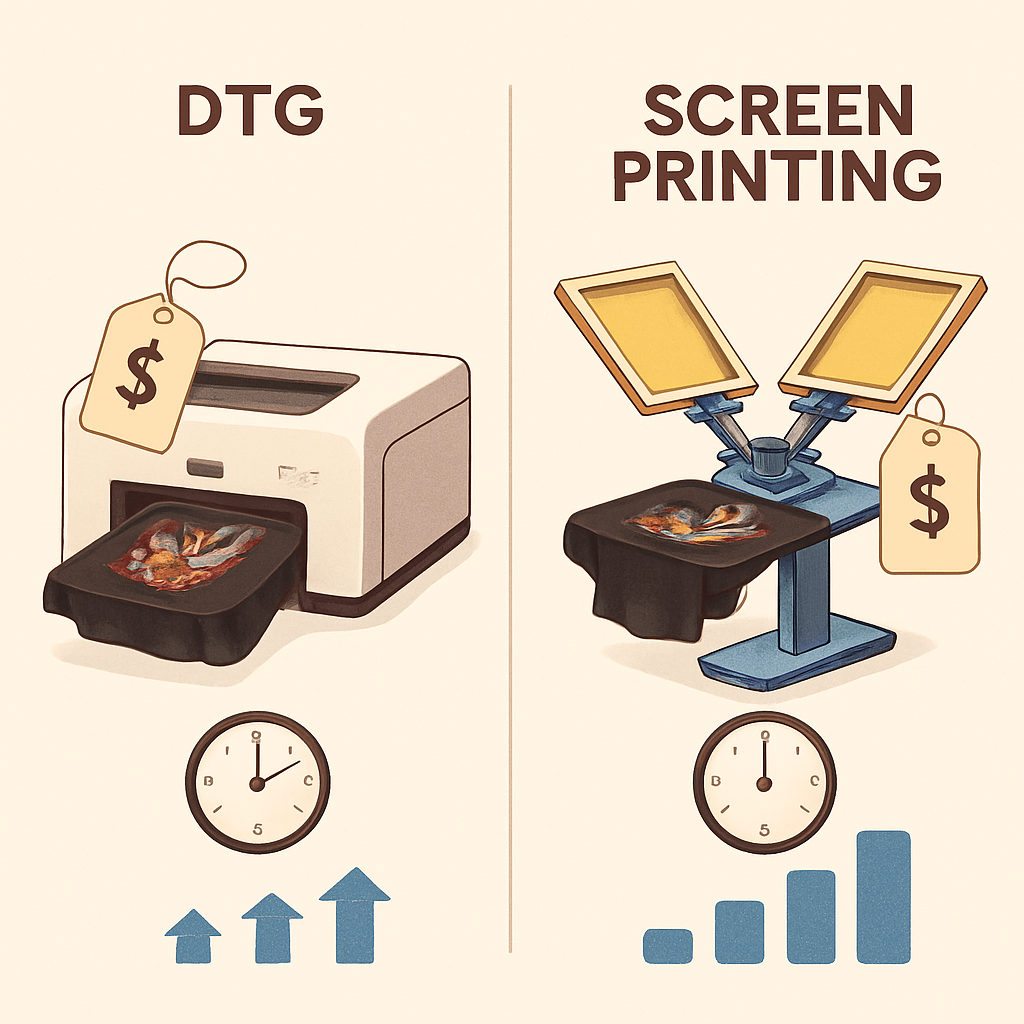

And don’t forget the timeline. DTG usually turns around faster for small batches, which is perfect for a one‑off gift. Screen printing shines when you order larger runs, because the setup cost spreads out.

Bottom line: there’s no one‑size‑fits‑all answer. The best choice depends on your design, the recipient’s expectations, and how you plan to care for the piece. Let’s dive deeper into the nitty‑gritty of each process so you can pick the perfect finish for your heartfelt gift.

TL;DR

When choosing between DTG and screen printing, think about image detail, color count, wash frequency, and order size to match your gift’s look and longevity.

In our experience, a photo‑rich tee shines with DTG for small batches, while bold slogans benefit from screen printing on durable fabric for larger runs.

DTG Printing Quality Explained

When you stare at a design file and wonder whether the final tee will look like the mockup, the first thing to ask yourself is: how much detail does the image need to survive the printing process? That’s the heart of the dtg vs screen printing quality debate – it’s not just about cost, it’s about what the eye actually sees after the ink settles.

DTG (direct‑to‑garment) works a lot like an inkjet for fabric. The printer sprays tiny droplets of water‑based ink directly onto each fiber, building up the picture pixel by pixel. Because it can lay down thousands of shades, you get smooth gradients, photographic depth, and that subtle fade‑to‑white you see in a family portrait. In our experience, a high‑resolution photo on a soft cotton tee comes out looking almost like a miniature canvas.

When DTG shines

Think about a gift for Mom: a collage of baby‑to‑teen pictures, each with a different hue. DTG captures the nuance without any extra setup. It also handles low‑run orders gracefully – there’s no need to create a screen for each color, so you can order a single custom shirt without paying a screen‑making fee.

But DTG isn’t a magic bullet. The ink sits just on the surface, so the fabric matters. A cheap, low‑pike cotton can soak up the ink unevenly, leading to a dull finish. That’s why we always recommend a pre‑shrunk, ring‑spun cotton for the crispest results.

When screen printing steals the show

Screen printing, on the other hand, pushes a thick layer of plastisol or water‑based ink through a mesh stencil. Each color gets its own screen, which means you’re limited to solid blocks of color, but those blocks are vibrant and incredibly durable. A bold “Best Dad Ever” in bright red? Screen printing will make that hue pop even after a hundred washes.

Because the ink sits on top of the fibers, the feel is a bit heavier, and the colors stay saturated. This is why many parents choose screen‑printed tees for kids’ birthday parties – the design needs to survive playgrounds, laundry, and endless hugs.

Here’s a quick sanity check: if your design uses fewer than five colors and you need maximum durability, screen printing is usually the safer bet. If you’re chasing photographic realism or need a one‑off gift, DTG often delivers the wow factor.

And if you’re still on the fence, check out How to Design a Custom Picture T Shirt: Friendly Step‑by‑Step Guide – it walks you through choosing the right fabric and prepping your file for either method.

Now, let’s talk about real‑world examples. A recent order we fulfilled for a set of matching parent‑child shirts used screen printing for the bold “Team Mom” slogan, while the baby’s matching shirt got a tiny DTG‑printed pastel illustration of a dinosaur – the contrast in texture was actually a fun design feature.

That video breaks down the ink‑laydown process for both methods, so you can see why the same design might look slightly different depending on the technique.

Beyond the tee, think about the whole gift ecosystem. A sleek fire‑proof document bag from Midnight Scriber makes a perfect companion for a custom shirt – both are thoughtful, high‑quality gifts that show you’ve put real care into the choice.

And for parents shopping for tiny ones, a well‑printed toddler beanie can be a game‑changer. Check out these chic toddler beanie ideas – the same DTG vs screen printing quality principles apply, especially when the design includes tiny logos or intricate patterns.

Bottom line? Quality boils down to three things: fabric, ink, and the number of colors. Match your design’s complexity with the right process, pick a garment that plays well with the ink, and you’ll end up with a gift that looks great straight out of the box and stays beautiful for years.

Screen Printing Quality Explained

When you’re trying to decide between DTG and screen printing, the quality question often feels like a tug‑of‑war. You picture a crisp photo tee on one side and a bold logo on the other, and you wonder which method will actually hold up after a hundred washes.

Let’s walk through what makes screen printing tick, especially when you’re buying a gift that’s meant to be worn, loved, and maybe even a little abused.

Why screen printing still wins on quality

First off, screen printing deposits a thick layer of ink right on top of the fabric. That layer acts like a tiny armor plate – it’s opaque, vibrant, and resistant to fading. Think of a “Best Mom Ever” slogan on a cotton‑blend hoodie: the ink sits on the surface, so the colors stay punchy even after repeated machine cycles.

That’s not just our opinion. Industry folks point out that traditional screen printing offers better opacity, richer blacks, and superior durability compared to digital methods (see traditional screen printing advantages). Those benefits translate directly into gifts that keep looking fresh.

And if you’ve ever felt the slight texture of a screen‑printed design under your fingertips, you know it’s not just visual – it’s tactile. That raised‑feel can make a design feel more premium, which is a subtle but real win for a special present.

Key factors that influence screen‑print quality

Ink type. Water‑based inks give a softer hand on cotton, while plastisol inks stay super vibrant on polyester. Choose based on the shirt’s material and the look you want.

Mesh count. A finer mesh (higher number) lets you capture more detail, perfect for intricate graphics. Coarser mesh is better for bold, solid blocks of color.

Screen tension. A tight, well‑stretched screen prevents ink bleed and ensures crisp edges. Loose screens can produce fuzzy lines that ruin a clean logo.

curing temperature. Under‑cured ink feels sticky; over‑cured can become brittle and crack. The sweet spot varies by ink, but most screen shops aim for around 320°F (160°C) for plastisol.

So, does that mean screen printing is always the better bet? Not necessarily. If you need a full‑color photograph with subtle gradients, DTG still has the edge. But for anything that relies on solid colors, sharp lines, or a thick‑ink feel, screen printing usually outshines digital.

Practical checklist for perfect screen prints

1. Pick the right fabric. 100 % cotton works great with water‑based inks; polyester blends pair nicely with plastisol.

2. Match mesh to design. Use 230–305 mesh for fine detail, 110–160 mesh for bold blocks.

3. Test a swatch. Print a small sample, wash it twice, and feel the surface. If it cracks or feels too stiff, adjust cure time or ink type.

4. Mind registration. Multiple colors mean multiple screens – each must line up perfectly. A mis‑aligned screen can turn a clean logo into a blurry mess.

5. Consider opacity. Light‑colored shirts often need a white under‑base, especially with darker inks, to keep colors vibrant.

6. Plan for wash durability. Use a gentle cycle and cold water for the first few washes; this helps the ink set fully.

These steps are the kind of nitty‑gritty that gift‑buyers appreciate – they’re the difference between a tee that looks museum‑ready after a year and one that fades after the first wash.

And because visuals often speak louder than words, here’s a quick video that walks through the screen‑printing process from exposure to curing. It’s a great way to see the details we just talked about in action.

After watching, you’ll notice how each color layer is built up on the screen, why tension matters, and how the final heat cure locks everything in place.

Bottom line: when you weigh dtg vs screen printing quality, think about what matters most for your gift – depth of color, tactile feel, and long‑term durability. Screen printing delivers a robust, vibrant finish that stands up to the hustle of everyday life, making it a solid choice for bold designs, team apparel, and any gift that should look as good after ten washes as it did on day one.

Color Vibrancy, Detail, and Resolution Comparison

When you’re picking a tee for Mom’s birthday, the difference between a muted print and a design that practically glows matters. That’s where the nitty‑gritty of dtg vs screen printing quality comes into play – especially when you care about color punch, fine detail, and how crisp the image looks after a dozen washes.

What “vibrancy” really means

Screen printing drops a thick layer of ink on top of the fabric, so the pigments sit right on the surface. The result is an opaque, saturated color that can look almost neon on a dark shirt. DTG, on the other hand, sprays water‑based ink that soaks into the fibers. It’s softer, but the same pigment can appear less intense because the fabric itself dilutes the hue.

One study from Printify notes that screen‑printed inks often achieve “vibrant, saturated, durable prints” while DTG inks are praised for “photorealistic detail” but can struggle with super‑bright shades like hot pink or neon green (Printify comparison). In practice, that means a bold “Best Dad Ever” in crimson will pop more on a screen‑printed tee than on a DTG‑printed one.

Detail and resolution – the pixel battle

DTG printers can push up to 1,200 dpi, which translates to razor‑sharp gradients and tiny facial features that stay recognizable even after a few washes. If you’re printing a family portrait, that resolution keeps every smile line and freckle intact.

Screen printing’s resolution depends on mesh count. A fine mesh (say 305) can reproduce decent detail, but you’ll still see a dot‑matrix effect when you try to mimic a photograph. The ink is thick, so tiny lines can blur together.

RTP Apparel’s own testing with pre‑treated shirts shows a noticeable jump in sharpness when the right DTG shirt is used – blacks and yellows become crisp, and the edges stay clean (RTP Apparel case study). That’s a reminder that the substrate matters as much as the printing method.

Real‑world scenarios you might recognize

Scenario 1: A pet‑lover’s custom hoodie. You want a high‑resolution portrait of a golden retriever with soft fur shading. DTG’s high dpi captures the subtle color shifts, and the ink’s softness feels like a gentle hug. The colors stay true for about 50 washes if you follow the care guide.

Scenario 2: A sports team’s rally tee. The design is a solid teal logo with white lettering. Screen printing lays down a thick plastisol layer that resists fading even after weekly practices and harsh laundry cycles. The colors stay bright for the garment’s lifetime.

Scenario 3: A grandma’s birthday collage. A mix of photos, pastel text, and a few bold accents. DTG handles the photo portions beautifully, while the pastel text might look a tad washed out compared to a screen‑printed version. If the pastel is crucial, you could split the job: DTG for the photos, screen for the text – a hybrid approach many shops offer.

Actionable checklist – getting the best of both worlds

- Identify the dominant visual goal: vibrant solid colors vs. photographic detail.

- Pick the right fabric: 100 % cotton for DTG; cotton‑poly blends work well with water‑based screen inks.

- Test a swatch: print a small patch of each method, wash twice, and compare color depth and edge sharpness.

- Consider pretreatment: a pre‑treated DTG shirt can boost vibrancy by up to 20 % according to RTP Apparel’s findings.

- Match mesh to detail: use 230–305 mesh for finer DTG‑style graphics if you go screen.

- Set realistic wash expectations: DTG ≈ 50 washes with proper care; screen ≈ lifetime durability for heavy‑use items.

Quick side‑by‑side comparison

| Feature | DTG | Screen Printing | Best Use Case |

|---|---|---|---|

| Color vibrancy | Soft, fabric‑integrated; may need pre‑treated shirts for peak intensity | Thick, opaque ink; ultra‑bright colors (neon, metallic) achievable | Bold logos, team colors |

| Detail & resolution | Up to 1,200 dpi; excellent for photos and gradients | Depends on mesh; fine mesh can handle moderate detail but can show dot pattern | Photo‑rich gifts, pet portraits |

| Durability | ~50 washes with proper care; water‑based inks | Lifetime on cotton; plastisol resistant to cracking | Everyday wear, sports uniforms |

Bottom line: if the gift’s heart is in a crisp, lifelike image, DTG wins the detail race. If you need colors that scream from the crowd and stand up to relentless washing, screen printing is your go‑to. By testing a swatch and matching the fabric to the method, you can guarantee the final tee looks exactly how you imagined – and lasts long enough for the next birthday, too.

Cost, Production Speed, and Scalability

Up‑front costs and per‑shirt pricing

In our experience, DTG feels like the “pay‑as‑you‑go” option. There’s no screen to make, no ink‑mixing labor, so the shop usually quotes you a flat rate that covers the pretreatment, the print head time, and a single cure cycle. For a one‑off birthday tee, you might see a price somewhere between $15 and $20.

Screen printing, on the other hand, starts with a setup fee – think of it as buying a ticket to a concert before you know how many seats you’ll fill. The shop has to create a mesh, pull the stencil, and align each color screen. That initial cost can be $50‑$100, which makes a small order look pricey. Once the per‑shirt cost drops dramatically, often below $5 for runs of 50 + pieces.

How fast can you get the shirts?

Speed is another place where DTG wins the “quick‑gift” race. Because it’s a digital process, the printer can fire off a dozen shirts in the same time it takes a screen shop to set up the first screen. Most print‑on‑demand shops promise a 3‑5 day turnaround for orders under 20 shirts.

Screen printing needs a bit more patience. After the screens are made, each color layer has to be printed, cured, and inspected before the next screen can be run. For a simple two‑color logo, you might still get the shirts in a week, but a multi‑color design can stretch that to ten days or more. The upside? Once the screens are in place, the press can churn out 100‑200 shirts a day without slowing down.

Scaling up: when does one method outgrow the other?

If you’re planning a family reunion gift set of 12 shirts, DTG stays simple and cheap. But imagine you’re ordering 200 “Best Mom” tees for a school fundraiser. At that point, the per‑shirt savings from screen printing become significant, and the faster line speed outweighs the upfront screen cost.

Another factor is design complexity. A photo‑rich image with many colors stays affordable on DTG no matter the run size, because you’re not paying extra for each hue. With screen printing, each extra color adds another screen, another setup fee, and another chance for mis‑registration. That’s why we often suggest a hybrid approach for large runs that need both photographic detail and bold solid blocks.

Quick cost‑speed checklist

- Order size < 20? DTG is usually cheaper and faster.

- Order size ≥ 50 and ≤ 2 colors? Screen printing wins on per‑unit cost.

- More than 3 colors or a full‑color photo? DTG keeps costs predictable.

- Need the shirts in under a week? DTG’s digital workflow is the safe bet.

- Planning a bulk run with a simple logo? Screen printing scales effortlessly.

Bottom line for gift‑buyers

So, what should you do next? Sketch out how many shirts you need, list the colors, and match that against the checklist above. If the numbers line up with DTG, you’ll get a fast, hassle‑free order that looks great straight out of the printer. If the math points to screen printing, you’ll benefit from lower unit prices and a durable finish that survives the laundry marathon.

Want a deeper dive into the cost breakdown? Printavo outlines the typical price components for both methods, which can help you compare quotes more confidently Printavo’s cost analysis.

Durability, Washability, and Longevity

When the gift‑giver thinks about a shirt lasting beyond the first wash, durability becomes the hidden hero of the dtg vs screen printing quality debate.

First, let’s unpack what we actually mean by durability. It isn’t just about how long the colors stay vivid; it’s also about how the print clings to the fibers when you tumble‑dry, scrub, or even stretch the fabric.

In our experience at heartful.gifts, DTG prints feel soft because the ink soaks into the cotton. That softness is great for comfort, but it also means the ink can wear away faster if the garment is laundered aggressively.

Screen printing, on the other hand, lays a thick layer of ink on top of the fabric. Think of it as a tiny armor plate. That armor resists fading, cracking, and peeling, especially on high‑traffic items like kids’ sports tees or weekly‑wear hoodies.

What durability really means

Durability is a combination of ink formulation, cure temperature, and fabric choice. Water‑based DTG inks cure at lower temps (around 180‑200 °F) and bond chemically with natural fibers. If the cure is too short, the print can feel sticky and fade after a handful of washes.

A recent article from Exile Technologies notes that modern computer‑to‑screen (CTS) equipment has tightened registration and reduced ink waste, which indirectly boosts long‑term durability because each layer is deposited more evenly Exile Technologies on durability improvements.

Washability tips for DTG prints

If you’re leaning toward a photo‑rich gift, here are three wash‑care tricks that can stretch a DTG print to about 50 washes:

- Turn the shirt inside‑out and use cold water. Cold water keeps the water‑based pigments from leaching out.

- Skip the dryer for the first three washes; air‑dry flat or on a low‑heat setting. Excess heat can open the ink pores before they’ve fully cured.

- Use a mild, non‑bleach detergent and avoid fabric softeners. Softeners leave a residue that can attract dirt to the printed area.

After you’ve followed those steps, you’ll notice the print still feels smooth rather than gritty, which is a good sign the ink is still bonded.

Longevity of screen‑printed designs

Screen printing shines when you need a garment that survives a laundry marathon. Because the ink sits on top, it forms a protective barrier that repels water and detergent. That’s why a custom “Team Mom” tee can look brand new after 100+ washes, especially when plastisol ink is used on a 100 % cotton shirt.

But even screen prints have limits. Over‑curing can make the ink brittle, leading to cracking on high‑stretch fabrics like jerseys. Conversely, under‑curing leaves a tacky surface that attracts lint. The sweet spot is a consistent 320 °F cure for plastisol and about 300 °F for water‑based inks on polyester blends.

If you’re gifting a hoodie that will get tossed in the dryer every week, ask your printer to run a “wash‑test swatch.” A small sample printed with the same settings will reveal whether the colors bleed or the surface starts to peel.

Quick durability checklist for gift buyers

Here’s a quick cheat‑sheet you can run through before you hit “order”:

- Choose fabric: 100 % cotton for DTG, cotton‑poly blend for screen if you want extra stretch.

- Verify cure temperature: DTG ~190 °F, screen ~320 °F.

- Ask for a wash‑test swatch before the full order.

- Follow care instructions: cold wash, inside‑out, low heat drying.

- Expect ~50 washes for DTG, lifetime for screen on cotton.

By matching the method to the shirt’s expected life‑cycle, you avoid the dreaded “my gift faded after the first laundry” moment.

So, when you weigh dtg vs screen printing quality, think of durability, washability, and longevity as three sides of the same coin. DTG gives you photographic detail for a one‑off keepsake, while screen printing guarantees that the design will stay vibrant through the everyday hustle of family life. Choose the method that aligns with how long you want the memory to last, and you’ll give a gift that truly keeps on giving.

Choosing the Right Method for Your Project

So you’ve stared at the two quotes, felt the tug of “photo‑rich detail” versus “bold, long‑lasting color,” and now you’re wondering which route actually serves the story you want to tell. That’s the heart of the dtg vs screen printing quality debate – it’s not just about price, it’s about matching the method to the moment you’re celebrating.

What’s the end‑use?

If the shirt is a one‑off birthday portrait for Mom, you probably want every freckle, every shade of pink in the cake frosting to stay true. DTG shines here because its 1,200 dpi heads lay down ink pixel by pixel, letting subtle gradients survive the first wash.

But if you’re ordering a batch of “Team Dad” tees for a family reunion, durability beats detail. A screen‑printed logo sits on top of the fabric like a tiny badge, and it will keep its punchy red even after the kids toss it in the dryer every weekend.

Fabric matters more than you think

DTG needs a natural‑fiber base – 100 % cotton or a cotton‑rich blend – to let the water‑based ink soak in. A polyester shirt will make the colors look washed‑out, and the print may crack after a few washes.

Screen printing is more forgiving. Water‑based inks work well on cotton, while plastisol inks love polyester blends. That flexibility means you can pick a performance fabric for a sporty hoodie and still get that thick‑ink feel.

How many colors are you juggling?

Every extra color in screen printing means an extra screen, extra setup time, and extra cost. If your design has more than three hues, the per‑shirt price can jump quickly. DTG, on the other hand, mixes colors on the fly, so a rainbow‑colored pet portrait stays the same price whether you print one shirt or twenty.

That said, if you’re working with a simple two‑tone slogan, screen printing will usually give you richer, more opaque coverage – something DTG can struggle with on dark fabrics.

Timeline – is speed a deal‑breaker?

Need the shirts in under a week for a surprise party? DTG’s digital workflow can spin up a dozen shirts in the time it takes a screen shop to cut its first stencil. In our experience, most print‑on‑demand partners ship DTG orders within 3‑5 days.

Screen printing needs the extra day or two for screen preparation, but once the screens are ready, the press can churn out 100‑plus shirts a day. So if you’re planning a large run and have a little patience, the initial delay pays off.

Budget checkpoint

- Under 20 shirts with a photo‑rich design → DTG is usually cheaper.

- 20‑50 shirts with 1‑2 solid colors → screen printing starts to win on per‑unit cost.

- More than 50 shirts or a design with many solid blocks → screen printing’s economies of scale dominate.

And remember, the upfront screen‑setup fee is a sunk cost that only makes sense when you spread it over a decent quantity.

Testing before you commit

Ask your printer for a wash‑test swatch. A tiny piece printed with the same settings will show you how the colors hold up after a few cycles. It’s a quick way to avoid the “my gift faded after the first laundry” nightmare.

If you’re still on the fence, try a hybrid approach: DTG for the photo centerpiece, screen for the bold tagline. Many shops can layer the two methods, giving you the best of both worlds.

Bottom line

Choosing the right method is all about aligning three factors: the visual goal (detail vs. vibrancy), the fabric you love, and the timeline and budget you have. When you weigh dtg vs screen printing quality, ask yourself: Do I need photographic fidelity or long‑term durability? Once you answer that, the right printer—and the right gift—falls into place.

FAQ

What’s the biggest quality difference between DTG and screen printing?

In a nutshell, DTG works like an ink‑jet for fabric – it sprays tiny droplets of water‑based ink that soak into cotton fibers, so you get photo‑realistic detail and smooth gradients. Screen printing, on the other hand, pushes a thicker layer of ink through a mesh stencil, giving you a more opaque, punchy finish that feels slightly raised. That’s why DTG shines on complex images, while screen printing excels at solid colors and durability.

Will a photo‑rich design look better with DTG or screen printing?

If the design is a family portrait, a pet’s face, or any image with subtle shading, DTG is usually the winner. The 1,200 dpi heads capture every freckle and pastel hue, and the ink integrates with the fabric for a soft feel. Screen printing can reproduce the same picture, but you’ll often see banding or a loss of nuance because each color needs its own screen.

How does the type of fabric change the quality outcome?

DTG needs a natural‑fiber base – 100 % cotton or a cotton‑rich blend – so the water‑based ink can soak in properly. On polyester or heavy blends the colors look washed‑out and may crack after a few washes. Screen printing is more forgiving: water‑based inks work on cotton, while plastisol inks love polyester and performance blends, giving you vibrant results on a wider range of fabrics.

Can I expect the same durability from DTG as from screen printing?

Not quite. Screen‑printed ink sits on top of the shirt like a tiny armor plate, so it usually survives 100 + washes without noticeable fading. DTG prints are softer, but the water‑based ink can start to fade after roughly 40‑60 washes if you don’t follow proper care (cold wash, inside‑out, low heat). For a keepsake that will be worn often, screen printing often has the edge.

What impact do color vibrancy and gradients have on each method?

Screen printing deposits a thick, opaque layer, which makes neon, metallic or very bright colors pop dramatically – especially on dark shirts. DTG’s ink blends in the fibers, so colors can look a bit more muted, but the advantage is seamless gradients and photographic realism. If you need a smooth sunset or a pastel palette, DTG will keep those subtle shifts intact.

Is there a size or order quantity where one method’s quality overtakes the other?

When you’re ordering fewer than 20 shirts with a detailed image, DTG gives you high‑quality detail without any setup cost, so the per‑shirt price stays reasonable. Once you hit 30‑50 shirts and the design is mostly solid colors, screen printing’s consistency and lower per‑unit cost start to shine, and you’ll still get that robust ink feel. The sweet spot for DTG quality is small, photo‑heavy runs.

How can I test the print quality before placing a big order?

Ask your printer for a wash‑test swatch – a tiny sample printed exactly the way your full order will be. Run it through a couple of cold washes, turn it inside‑out, and check both color vibrancy and how the ink feels. If the DTG sample stays smooth and the colors don’t bleed, you’re good. For screen prints, look for a firm, non‑sticky surface and make sure the edges stay crisp after washing.

Conclusion

We’ve walked through every angle of dtg vs screen printing quality, from the way ink settles into cotton fibers to the thick‑layer armor of screen prints.

So, what does that mean for you, the gift‑buyer? If you’re chasing a photo‑rich keepsake—think grandma’s birthday collage or a pet portrait—DTG’s high‑dpi detail and soft hand usually win, especially for runs under twenty.

But when the goal is a bold logo for a family reunion tee that will survive endless laundry cycles, screen printing’s opacity and durability give you peace of mind.

Remember the three quick checks we’ve highlighted: the visual goal (detail vs vibrancy), the fabric you love, and your timeline/budget. Match those three, and the quality battle settles itself.

One last tip: always ask for a wash‑test swatch before you commit. It’s the fastest way to see how the colors hold up and avoid that dreaded “faded after the first wash” moment.

And if you’re still undecided, try ordering a single sample of each method. Compare the feel, the color punch, and how they survive a quick wash – that side‑by‑side test often makes the choice crystal clear.

Ready to pick the perfect method for your next gift? Head over to heartful.gifts, where we’ll help you turn your vision into a shirt that looks great today and lasts for years.